Introduction

Behind every powerful excavator at work lies a set of reliable, precision-built components. Today, we invite you to step inside our excavator parts manufacturing workshop and take a closer look at how key components like pins, bushings, and bucket teeth are brought to life.

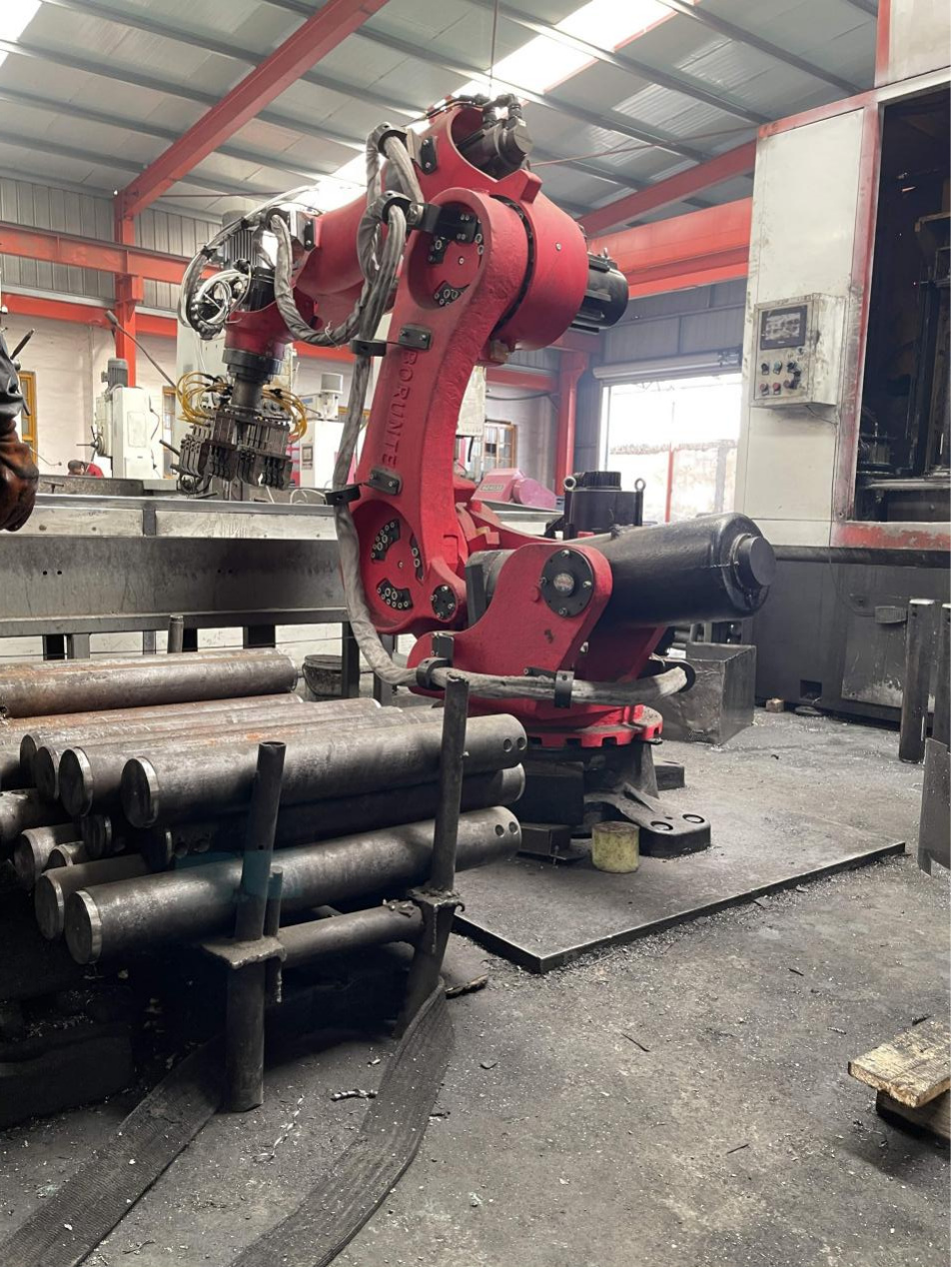

Workshop Overview

Our workshop covers over 1,000 square meters, equipped with advanced machinery such as CNC machining centers, lathes, heat treatment furnaces, and precision measuring tools.

• Daily output: up to 500 units of pins

• Staff: over 200 skilled technicians, many with more than 10 years of experience.

• Production standards: ISO-certified, with customized solutions available.

Step-by-Step Production Process

Here’s a look at how our most popular product — excavator pins — is made:

1. Material inspection & cutting

2. Rough machining → precision machining → chamfering

3. Heat treatment to enhance hardness and wear resistance

4. Surface treatment such as galvanizing or black oxide

5. Final inspection and packaging

Strict Quality Control

Every part we produce undergoes a comprehensive quality inspection before leaving the factory, including:

• Dimensional accuracy

• Surface hardness

• Concentricity tests

• Visual inspection for surface defects

We use precision instruments like CMM (Coordinate Measuring Machine), Rockwell hardness testers, and more.

Customized Solutions for Global Clients

We offer OEM and custom-made parts based on your drawings or requirements. Whether you need:

• Non-standard dimensions

• Special surface finishes

• Logo engraving or private labeling

Our team can provide fast prototyping and short lead times for both samples and bulk orders.

Conclusion

From raw material to finished product, every excavator part goes through dozens of steps — each one focused on precision, durability, and your satisfaction. Because we believe:

“No part is too small when it comes to quality.”

Related Links

• [View Our Best-Selling Excavator Parts]

• [Maintenance Tips for Pins & Bushings]

Post time: Jun-27-2025