Products

-

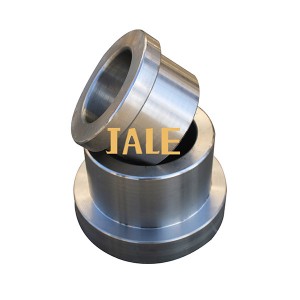

Excavator Boom Bushing SK210

Crack Resistance and Abrasion Resistance: After quenching and tempering, the pin undergoes mid frequency induction hardening, which ensures sufficient core strength and wear resistance of the external surface.

-

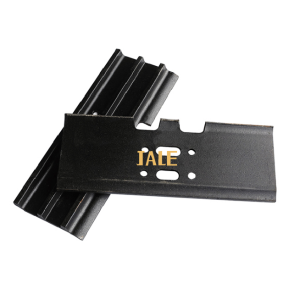

Excavator Track Shoe CATERPILLAR CAT70

Our products include Single Teeth Dozer Track Shoe and Triple Teeth Track Shoe for Excavator. The pitch from 101MM to 228MM.We use Boron-Alloy Roller Steel and punching according to the different dimensions by Heavy Machines. All the track shoes produced under Complete High Temperature Quenching and Tempering.

-

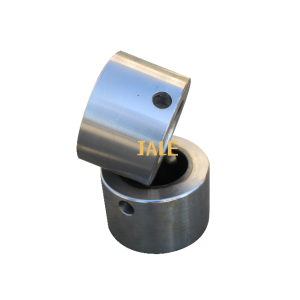

Excavator Track link Assy Komatsu PC200-5 20Y-32-00023 KM2451/49

The combined crawler chain is carefully cast with high-precision craftsmanship. There is perfect participation in every section. To ensure the excavator’s walking speed and excellent rotation performance with high standards of quality requirements. Its light weight, high strength, simple structure and reasonable price can create more value for customers.

-

Excavator Bucket ear D6D

Advanced production equipment, perfect detection technology and strict production management are the guarantee for our product quality.

The whole production process from the research & development of product to the purchase, processing, detection, packaging and acceptance of raw materials and product delivery is implemented in strict accordance with international standard quality management system. -

Excavator Track Shoe Bolt Nut 9M7444

JALE has a complete range of bolts and nuts available for all brands of excavators and bulldozers. Our bolts and nuts are of excellent quality and can be used in multiple situations. All track bolts are of quality grade 12.9.There are made of High Alloy Steel all through Heat-Treated and Induction of OEM specifications to withstand High Abrasion and Stresses.

-

Excavator Bucket Pin Bolt And Nut Caterpillar CAT320

JALE has bolts and nuts suitable for all brands of excavators and bulldozers. Our bolts and nuts are heat treated with high alloy steel to withstand high wear and stress, and can be used in a variety of situations.

-

Excavator Bulldozer DOOSAN DH225 12.9 Grade

After quenching and tempering, the pin undergoes mid frequency induction hardening, which ensures sufficient core strength and wear resistance of the external surface.

After carburization, they undergoe internal and external mid frequency induction hardening, which ensures reasonable core hardness and wear resistance of internal and external surfaces. -

Excavator Wheel Loader Bolt And Nut HYUNDAI R110 R120

JALE has a complete range of bolts and nuts available for all brands of excavators and bulldozers. Our bolts and nuts are of excellent quality and can be used in multiple situations. All track bolts are of quality grade 12.9.There are made of High Alloy Steel all through Heat-Treated and Induction of OEM specifications to withstand High Abrasion and Stresses.

-

Excavator Track Roller Bolt And Nut KOMATSU PC300 PC200

Product Name: Excavator Track Roller Bolt And Nut KOMATSU PC300 PC200

Application Model: Track Roller KOMATSU PC300 PC200

Material: 40cr steel -

Excavator Carrier Roller Bolt And Nut CATERPILLAR CAT312

JALE has a complete range of bolts and nuts available for all brands of excavators and bulldozers. Our bolts and nuts are of excellent quality and can be used in multiple situations. All track bolts are of quality grade 12.9.There are made of High Alloy Steel all through Heat-Treated and Induction of OEM specifications to withstand High Abrasion and Stresses.

-

Excavator Track Chain KOBELCO SK330-8

We use boron alloy steel rolling and heavy machinery to punch according to different sizes, so that they are all produced under complete high temperature quenching and tempering. The surface hardness ranges form HRC48-56,depth from 6mm-12mm.

-

Excavator Sprocket Rim Caterpillar CAT 215 CAT225

Motion provided by power generator of an excavator is conveyed to track link by running motor and sprocket rim. The teeth of sprocket rim should fit the track link well and should be able to drive the link steadily. Even when the link stretches due to wear and teat of its pin and bushing, the teeth should fit well. Usually, a sprocket rim is placed at the back part of the running device of an excavator.